When Dr. Michael Slag was diagnosed with a rare tumor, he immediately knew the risks of the surgery that would be needed to remove it. The Pancoast tumor sitting at the top of his right lung is such a rare type of cancer that the Mayo Clinic, where Dr. Slag went for treatment, has only seen 60 cases in the last 20 years.

The potential complications were many. The tumor was wrapped around the top of his rib cage and intertwined with several critical nerves and blood vessels, which meant that its removal carried a high risk that Dr. Slag would lose at least part of the function of his right arm. For an endocrinologist whose job requires some very delicate work, even a minor loss of function could have been catastrophic.

To minimize the risk, a lot of preparation was needed, and that’s what 3D printed models are for. The surgical team that would operate on Dr. Slag was fortunately armed with Mimics Innovation Suite software from Materialise.

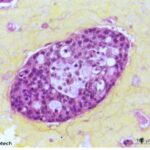

Using Dr. Slag’s MRI and CT scans, the team created a 3D model of the tumor and its surrounding area. The model, which took 70 hours to print, allowed the doctors to see the exact positioning of the tumor and how it interfered with the blood vessels and nerves.

“We frequently may have a plastic surgeon, an orthopedic surgeon, a vascular surgeon, and myself: all involved in a Pancoast tumor resection,” said Dr. Shanda Blackmon, a thoracic surgeon at Mayo Clinic. “And when that’s the case, there’s nothing better than having a model, for the whole team to meet around and plan the case…Clearly everyone’s tumor is different, and it’s always in a different location.”

With a 3D map in front of them, the surgical team knew the precise location of Dr. Slag’s tumor, and were able to plot their course ahead of time, virtually eliminating any surprises that may otherwise have come up during the surgery. Only a few years ago, a procedure like this one would have involved fully opening up the patient’s chest, resulting in a long, painful recovery and lots of potential complications. With the preparation that the 3D software and printed model allowed, the surgery was reduced to a quick, minimally invasive laparoscopic procedure.

“So the surgery that we performed was basically putting a camera in the side of the chest through a small hole that was created,” said Dr. Blackmon. “We had two additional ports, that are basically tubes that we put in between the ribs, that we passed instruments through. And that was all we did to resect his tumor.”

Dr. Slag left the hospital three days after the surgery, with almost no pain, and with both arms and hands fully functional.

“It’s unbelievable,” he said. “In fact, I was walking the first night after the surgery.”

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.