Versatile is a term we hear bandied about as a necessary feature for many items and processes, but often we aren’t quite sure how it applies specifically–to anything, anymore. With 3D printing, versatility is plain as day, and it is truly what makes the technology so attractive to people with ideas–whether they are planning on going really big or really, really small.

Bioengineers at the UCLA Henry Samueli School of Engineering and Applied Science have some ideas all right. Looking toward applications which could prove powerful in biomedicine but also other industries, these researchers aren’t just going small with their project–they are going microscopic–using software to design objects as small as 100-500 micrometers in size, and features as small as 10-15 micrometers. The first question is, as one shakes the head, how in the world do they do something like this? And two, why do they want–or need–particles as small as the width of a human hair?

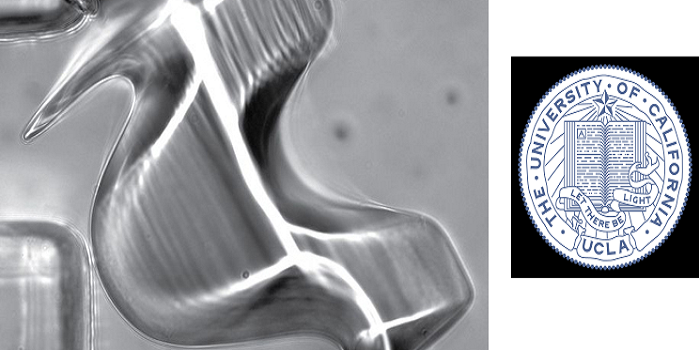

Chueh-Yu Wu, Keegan Owsley, and Dino Di Carlo have outlined exactly why–and far more–in their paper recently published in Advanced Materials, called “Rapid Software-Based Design and Optical Transient Liquid Molding of Microparticles.” With a completely new technique that would not be possible without 3D printing, the team is able to use UV light patterns to manipulate objects shaped by a photopolymer precursor stream. Optical transient liquid molding (TLM) is the name of the process which employs the 2D light patterns to create objects researchers have found elusive up until this point, even with 3D printing.

“…mass production of microscale features or objects is difficult to achieve. Optical lithography approaches that leverage microfluidic delivery of precursor photopolymer streams such as stop-flow lithography, possess many of the advantages of 3D printing technologies and have expanded fabrication to microscale objects (i.e. particles) with a relatively high manufacturing rate that is on an upward trajectory,” states the research team in their paper.

Rather than accepting limitations in this area, the bioengineers kept working for a solution, and found one through the shaping of the polymer precursor stream before extrusion. With these streams they can create 3D fibers and particles, but challenge remained in ‘shrinking’ them to the microscale. Using TLM, they are able to achieve smaller channel flow as well as using the unique ‘stopping flow.’

“TLM is a universal strategy to rapidly refresh and control high-speed flow inside microchannels enabling 3D design of particle shape and layered structures in silico, fabrication of the design in reality, and finally application to advanced microparticle systems,” states the team in their paper.

The two fluids used are combined in pillars which in turn control the shape of the liquids coming together. These fluids are the liquid polymer and the liquid mold. Using this technique means that the shape is dependent on the arrangement of the pillars, which the researchers can vary using their previously developed software, uFlow, available for free download to anyone.

“It’s like we squeeze dough through a mold, which is the liquid mold, to make a noodle and then cut the noodle into pieces using another mold — the patterned UV light,” said Chueh-Yu “Jerry” Wu, lead author and graduate student of Di Carlo.

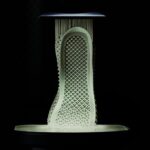

These microparticle systems could lead to new breakthroughs in bioprinting as they may allow for self-assembling interlocking particles leading to tissue regeneration. And regarding their relevance to other industries, the bioengineers see the microscopic 3D shapes being applicable in creating new coatings or paints with light-reactive properties.

“We know that shape often determines material function, so while we have a few ideas of what this could lead to, this fundamental capability to produce made-to-order 3-D microparticles could be applied in ways we have not contemplated,” said Dino Di Carlo, the principal investigator on the research and a professor of bioengineering at UCLA. “There are so many potential applications — in that sense, it’s really exciting.”

The researchers are now able to 3D print one of these objects every five seconds. Let’s hear your thoughts on this method of printing in the Microparticle 3D Printing forum thread on 3DPB.com.

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.