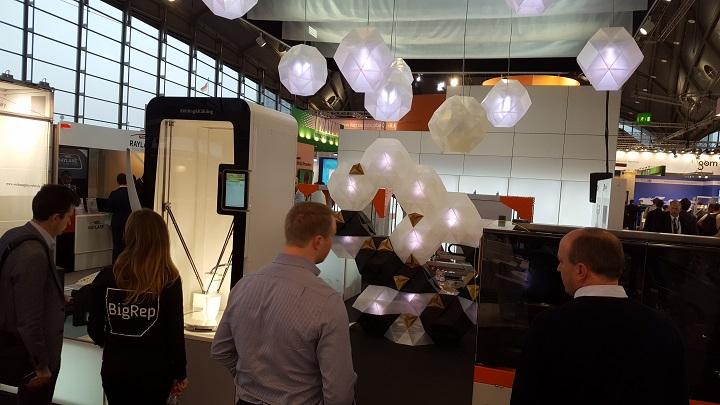

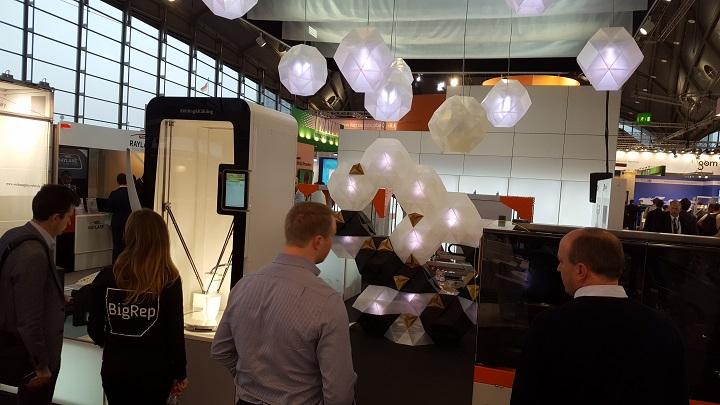

Formnext 2016 may be over, but that’s all the better for us to now digest all the announcements made in Frankfurt. Among the first big announcements were those coming from BigRep one week ago today, as the company held a press conference to detail not one, but two new 3D printers — as well as new partnerships and efforts across the industr

Since they rolled onto the 3D printing scene just a few years ago, BigRep has been impossible to ignore, as they clearly live their motto: “From big ideas to big prints.” If there’s one company we can count on for truly going big, it’s this Germany-based company, which introduced the BigRep ONE in early 2014 and has been busy ever since. CEO René Gurka told us that the company has now sold 140 of their large-scale FDM 3D printers globally, with focus in several key markets including Europe, the US, and Asia. With headquarters in Berlin and offices in Singapore and, recently announced, Brooklyn, BigRep now operates through 40 resellers and has a team of 70 employees with an international background, with the team originating from 14 nations.

To demonstrate the uses for their technology, BigRep highlighted a particular use case, as UK-based CJR Propulsion uses their BigRep ONE 3D printers to take production of ship propellers down from a matter of weeks to just one weekend, saving an incredible amount of time and money. CJR has been recognizing the benefits of and fully embracing 3D printing technology in its process, with the company’s technical sales manager, Alex Stevens, noting upon the company’s acquisition of its third 3D printer:

“As far as I’m aware we are the first propeller and sterngear manufacturer who has embraced this cutting edge technology for production of patterns. This is further demonstration of how CJR is continuing to push the boundaries. We did our research and a lot of engineering work to match the printers’ functionality to our requirements, but now we are reaping the benefits with very fast and accurate production of patterns.”

https://youtu.be/s0z6G35PFGg

With this use case in mind, Gurka proceeded to the big news for the conference, starting with the company’s two new products.

The new BigRep Studio 3D printer was developed following three years of experience in the industry, the company notes, and directly responds to demonstrated desire for the capabilities of a BigRep 3D printer without the massive footprint of the BigRep ONE. With a size of 1022 x 1660 x 1500 mm and a build envelope of 500 x 1000 x 500 mm, the smaller (250kg) BigRep Studio is set to solve an unexpected problem BigRep had run into:

“Sometimes the product we have is too big for customers. So we decided to go one step down. It’s funny that size can keep from making sales,” Gurka pointed out.

Additional specs for the FDM BigRep Studio include:

- Layer resolution: 300 microns

- Extruder: Single extruder with cooling fan, 0.6mm nozzle

- Materials: PLA, PETG

- Availability: Q2 2017 — taking pre-orders now

- Approximate price point: €29-30K (with pricing higher due to shipping in Asia and the US)

BigRep’s second new printer announcement is the BigRep Tech, which came into being via a partnership with Kühling&Kühling, which had also teamed up with Polymaker.

“The BigRep Tech is the first 3D printer in BigRep’s product portfolio which can process technical plastic polycarbonate. This plastic is characterized by incredible strength, high impact resistance, robustness and hardness, and is ideally suited for applications in the med-tech field,” BigRep notes.

More materials will additionally be introduced in the comping months. The delta-style 3D printer has an 800 x 740 x 2200 mm footprint, a 400 x 600 mm build volume, and employs FDM technology. The partnering companies will be working together for distribution in Europe, and BigRep will be the exclusive distributor outside of that region. The BigRep Tech targets the medical market first, and is capable of making end-use parts in polycarbonate, offering significant benefits to that industry. As Gurka noted, “Additive Manufacturing 3.0” keeps the focus on the creation of functional parts via 3D printing technology, a focus we are seeing more and more throughout manufacturers and desired among end users.

Additional specs for the BigRep Tech include:

- Layer resolution: Minimum layer thickness approx. 0.05mm

- Extruder: High temperature print head (500°C max.)

0.5mm nozzle pre-installed – 0.75mm nozzle diameters available separately - Weight: 250kg

- Availability: Shipping Q2 2017 — taking orders now

- Approximate price point: €44K, including a two-year service pack

Additionally, BigRep announced a new additive manufacturing solution in working with Netherlands-based TNO. In about 18-20 months, we should see the first machine arising from this partnership. The companies will be working together to create an automated 3D printing production system that is set to enhance printing speed capabilities by simultaneously creating multiple objects.

TNO has been hard at work for some time now on their ‘racetrack’-style production system that seeks to speed up print times by a factor of up to ten times. TNO’s PrintValley production system has been acclaimed as quite an achievement, and BigRep will now gain access to and investing in this technology. The multi-million-euro partnership agreement, signed at formnext, brings together BigRep and TNO in the AMSYSTEMS research project. Development on this joint project will be something to truly keep an eye on, and within the next two years we should be seeing some truly groundbreaking achievements arise from this ambitious partnership.

With all that BigRep has been up to lately, the announcements at formnext represent a huge step forward not just for the company’s vision, but the development of the 3D printing industry itself as we continue to see fruitful partnerships arise and take additive manufacturing that next step toward the much-vaunted industry 3.0. Discuss in the BigRep forum at 3DPB.com.

[All photos taken by Sarah Goehrke for 3DPrint.com at formnext]

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.