Over the last few years, 3D printing has opened up a wide variety of possibilities for guitar manufacturing. Top manufacturers such as Fender have adopted 3D printing technologies as an integral part of their quest to develop the highest quality of equipment, and it has led to significant improvements in cost and the production cycle. Aside from making improvements to the design process, the integration of 3D printing has fostered the capability to manufacture guitar parts and properties that were previously impossible through traditional methods.

The Research & Development Tax Credit

Enacted in 1981, the federal Research and Development (R&D) Tax Credit allows a credit of up to 13 percent of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- New or improved products, processes, or software

- Technological in nature

- Elimination of uncertainty

- Process of experimentation

Eligible costs include employee wages, cost of supplies, cost of testing, contract research expenses, and costs associated with developing a patent. On December 18, 2015, President Obama signed the bill making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax and startup businesses can utilize the credit against $250,000 per year in payroll taxes.

Fender

Fender has established itself as one of the leading manufacturers of amplifiers, guitars, pedals, and PA sound equipment around the world. By integrating 3D printing into their manufacturing processes, they have improved their time to market by nearly 40%, due in large part to their in-house design center powered by the Objet Eden350V 3D printer from Stratasys. 3D printing has become an integral part of Fender’s everyday operations, with around-the-clock projects ranging from small amp knobs to full guitar body designs. The implementation of 3D printing has allowed Fender to develop prototypes more quickly and cost-effectively than ever before.

For example, Fender recently re-released the Fender Passport as an all-in-one transportable PA system. Their R&D team applied 3D printing to manufacture the distinct housing pieces, and provided Fender with the capability to install electronics and speakers as well as conduct sound and heat tests before undergoing the tooling process, which significantly reduces the cost of the project.

Over the last few years, Fender has integrated 3D printing technology to streamline their design processes, reduce production cycles, and accelerate the time-to-market while decreasing the risk aspect of product development. In fact, Fender was able to expedite their market timetable for the G-DEC amplifier by 50% by utilizing 3D printing technologies for the smaller pieces such as the knobs. The G-DEC underwent numerous design iterations before reaching the market only six months after the initial concept was unveiled, as opposed to the 12-month span that traditional design methods would have required.

In addition to lower costs and shorter production cycles, 3D printing has fostered enhanced collaboration between Fender’s R&D and marketing departments. Rather than presenting marketing with a diagram or drawing, 3D printing has granted the R&D department the ability to demonstrate the actual, tangible product.

ODD Guitars

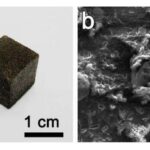

ODD Guitars, founded by prolific designer and additive manufacturing expert Olaf Diegel in 2011, specializes in the development of customizable guitars that explore the potential applications of 3D printing as a means of manufacturing guitar parts. Utilizing 3D printing technology known as Selective Laser Sintering (SLS), they were able to develop designs that could not be manufactured through traditional means. This procedure involves constructing the components by spreading a thin layer of nylon powder, which is then fused in the appropriate locations for that particular portion. The layer is subsequently dropped down a fraction of a millimeter and reinforced with another layer of powder on top of the first layer until the component is built.

Since its inception, ODD has built a solid reputation of manufacturing high-quality, customizable guitars using the latest in 3D printing technology. They are able to utilize different material, such as mahogany or maple for the inner core, to influence the sustain and acoustic tone of the guitar. The fret board can change between ebony and rosewood, with ebony typically yielding a brighter tone. The advent of 3D printing has cultivated the growth of ODD and its customers by providing them a wide array of options in terms of aesthetics and sound parameters. 3D printing has helped promote mass customization, which is integral as a means of creating musical instruments tailored to the needs of the musician, such as decreasing the weight of the instrument.

Conclusion

3D printing has found a unique niche in the realm of guitars and music equipment. The fact that world-renowned experts in this field such as Fender are advocating and implementing this technology proves that the benefits of 3D printing are legitimate and significant. The success of ODD, whose primary focus is the production of guitars and guitar parts via 3D printing, further exemplifies the depth of this market, and it will only continue to expand as the technology evolves. Unfortunately, Gibson, the longtime leading guitar manufacturer, has recently gone out of business. However, Gibson guitar owners in need of components may have the ability to utilize 3D printing to acquire replacement parts that will presumably over time become increasingly difficult to find from distributors.

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

Tyler Gianchetta and Charles Goulding of R&D Tax Savers discuss 3D printed guitars.

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.