Every year at RAPID + TCT, one company is given the Innovation Award for its novel, potentially industry-changing technology. In 2017, the award went to Impossible Objects. This year, out of the more than 300 exhibitors at the show, a brand new company was given the award.

Every year at RAPID + TCT, one company is given the Innovation Award for its novel, potentially industry-changing technology. In 2017, the award went to Impossible Objects. This year, out of the more than 300 exhibitors at the show, a brand new company was given the award.

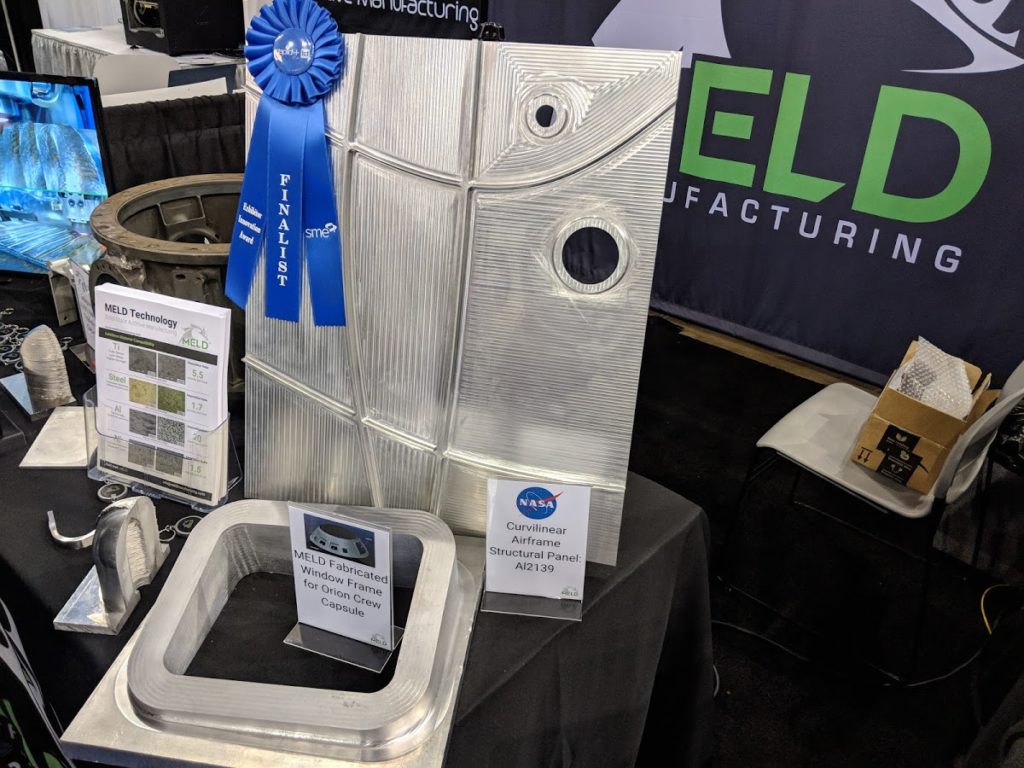

MELD Manufacturing was launched in early April as a subsidiary of Aeroprobe Corporation, a producer of air data and flow measurement systems and instruments that provide real-time air and flow data. But while MELD may be brand new, its technology is not. MELD additive manufacturing technology has been in development for more than a decade, and it’s certainly deserving of an award for innovation, as it’s unlike anything that has come before it.

One thing that most 3D printing processes have in common is that they involve melting material, whether that be metal, plastic, ceramic, etc. That’s not the case with MELD technology. It is a solid-state process, meaning that the metal does not reach the melting temperature during manufacturing. By avoiding melting the metal, MELD avoids issues such as porosity and hot-cracking, and produces high-quality parts with low residual stresses and full density while requiring less energy than melt-based processes.

MELD technology is a single-step process that does not require time-consuming follow-on processes such as hot isostatic pressing or sintering to improve the quality of the 3D printed material. It’s more efficient than other processes and is also capable of making larger parts thanks to its open-atmosphere operation and scalable equipment. MELD is at least 10 times faster than fusion-based additive manufacturing processes. In addition to 3D printing, it can be used to repair, coat and join a wide range of materials, including some metals that cannot be welded with traditional processes. A MELD additive manufacturing machine is not limited, unlike many metal 3D printers, to just a few metals – it can work with everything from aluminum to titanium and steel to nickel-based super alloys using the same machine and the same process.

“The MELD technology is a revolution,” said MELD Manufacturing Corporation CEO Nanci Hardwick. “To be recognized at RAPID by these industry leaders demonstrates just how much potential MELD has to change the way we think about manufacturing. We want to see MELD adopted across industries, so it’s exciting to see genuine interest from such a diverse crowd.”

MELD’s 3D printer, or MELD machine, is the B8, which uses solid metal bars to fabricate parts. It offers a build area of 36″ x 12″ x 12″ and requires little raw material costs compared to powder and wire-based processes. It’s a truly new way of approaching additive manufacturing, and the judges for the Innovation Award, which included representatives from industry, academia and government, clearly saw a lot of potential in this young company.

“To earn this award our first year at RAPID is an honor,” said MELD Additive Manufacturing Manager Chase Cox. “MELD is on its way to innovating a number of industries and this award is a great milestone.”

MELD Manufacturing has several more conferences coming up over the next month; you can find it at AeroMat in Orlando, MegaRust in San Diego and ASME Turbo Expo in Norway. MELD currently offers machine sales, contract manufacturing, and several other services.

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below.

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.