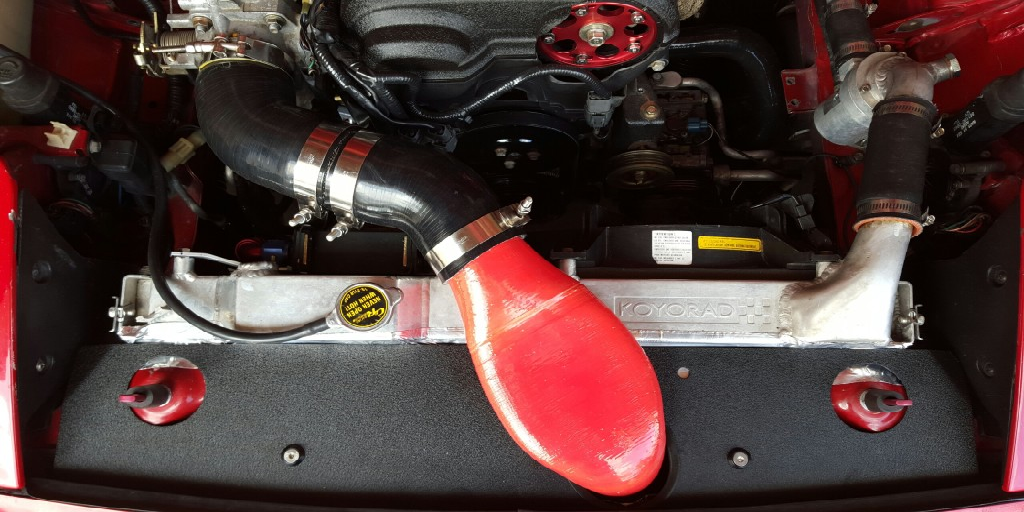

There is much evidence about how functional and convenient 3D printing can be. Businesses and individuals constantly report that they are using the technology to reproduce or improve small to large replacement parts, making their repair time much quicker. Examples I have written about before range from huge companies like Caterpillar Inc., which uses 3D printing to save time on the assembly line, to individuals like Frankie Flood, who used 3D printing to sand cast a wing nut he could no longer order. Given what a significant financial investment automobiles are, you can imagine how convenient it can be to be able to 3D print replacement car parts. But also consider 3D printed engine modifications that add original “aftermarket” parts you can successfully 3D print — like this cold air intake for an older model Mazda Miata that will power up your engine right quick!

This example of a new engine part print job was executed by a Reddit user called “TheRealSpaceTrout,” who took the original design from “hard surface freelance artist” Alec Moody. Moody has worked in the game industry for 14 years, and he co-owns handplane, which develops tools for video game artists. But he also designs 3D printable models, including his “aftermarket” cold air intake system for Miatas made between 1994 and 1997. Cold air intakes are engine modifications, which means they aren’t included in the original vehicle. This modification moves the engine’s air filter outside so that cooler denser air is sucked into the engine; this brings more oxygen, and hence more power, into the combustion chamber.

Here, Moody explains the design, which is open source with available files:

“The design started with a urethane expanding foam pour to capture the availible negative space, that was 3d scanned and I have made about a dozen design iterations over the course of 9 months. I was careful in the design to make smooth transitions between shapes and keep a very consistent cross sectional area at every point of the duct.”

When TheRealSpaceTrout 3D printed the intake modification, he used ABS plastic, acetone vapor bath, and XTC-3D coating. A hole cut into a K&N filter allows for air to enter the tube.

Moody also reports he has only printed the part in ABS, because he states that PLA will “almost definitely melt or deform.” Moody prints everything in multiple sections, and bonds them with ABS cement — “MEK solvent with ABS filler” — which he found in the Home Depot plumbing section.

If you have a Mazda Miata, or know someone who does and would like to add some 3D printed power to the car, you can check out this cold air intake, which proves to be more cost effective and easier to install than other car engine modifications. Discuss in the 3D Printed Cold Air Intake forum over at 3DPB.com.

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.