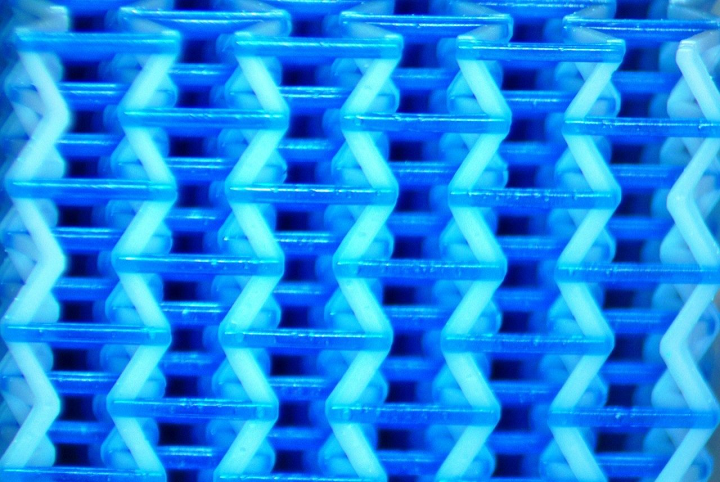

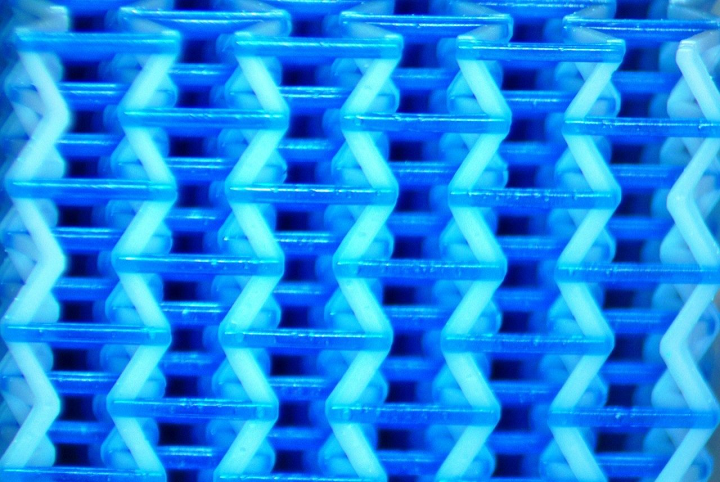

A team of researchers from Virginia Tech University have developed a new method of microscale 3D printing, which uses in-situ resin mixing and robotics to 3D print multimaterial with programmed stiffness – without cross contaminating any of the properties. The researchers have dubbed their new method multimaterial programmable additive manufacturing with integrated resin delivery – say that five times fast – and it could be used in a variety of different applications, such as actuation, aircraft wing structures, artificial muscles, energy absorption, flexible armor, microrobotics, and protective coatings.

Stretching normal material in one direction means that it will shrink in the other direction. But, Virginia Tech’s patented multimaterial process and design makes it possible to create specific modulus (flexibility) distributions in a build, which then allows for programmed shrinkage or expansion to take place throughout the material body; this is known as programmed morphing.

Xiaoyu “Rayne” Zheng, who is an assistant professor of mechanical engineering in the university’s College of Engineering, as well as a member of the Macromolecules Innovation Institute, explained that this new microscale manufacturing system is also able to be up-scaled to centimeter levels…and even levels above that.

“We use this new technique to create materials with programmed stiffness. Basically, you can program where the modulus is distributed in 3-D. With this programming we can achieve morphing capability—to stretch and deform in different directions,” Zheng explained.

“The technique is a robotic-based additive manufacturing, an integrated fluidic system that allows us to deliver different ink [resin] as feedstock. The process is also self-cleaning so that there is no cross-contamination between inks.”

Zheng certainly knows what he’s talking about, having worked with 3D printing at the nanoscale in the past. He said that 3D printing hopes to get to a place where multiple materials can be used to 3D print a functional device without having to rely on inordinate amounts of extra construction, like welding, tooling, gluing, and fitting.

“Achieving this goal requires us to put an array of different material properties into a single platform and connect them,” Zheng explained. “The added degree of material design freedom allows us to achieve negative, positive-to-zero morphing strains without changing the 3-D micro-architecture of a material.”

The team has just published a paper on their innovative new microscale 3D printing method in the Scientific Reports journal. This new method uses a robotic material cleansing system so that materials of different modulus can be switched without causing any cross contamination between properties; in-situ resin mixing, delivery, and exchange is also featured in the new technique.

As opposed to traditional 3D printed materials with similar base materials, multimaterial metamaterials feature varying rigidity – for example, rigid brittle in a 3D lattice framework all the way down to a soft elastomeric. This is definitely a change from current 3D printing methods, which can have somewhat limited capabilities in terms of incorporating multiple materials in complex, 3D architectures with microscale resolutions.

“We envision these programmable morphing material concepts will find applications in directional strain amplifications, actuations, flexible electronics, and the design of lightweight metamaterials with tailored stiffness and toughness. The new material design space offered by rapid fabrication of dissimilar material constituents distributed within a micro-lattice architecture opens up new dimensions of 3-D printing of multimaterials with a large degree of stiffness variance,” Zheng said.

What do you think of this story? Let us know your thoughts; join the discussion of this and other 3D printing topics at 3DPrintBoard.com or share your comments below.

[Source: Phys.org]

If you're looking to request photorealistic CGI in the USA, our service offers an easy and efficient way to get stunning, lifelike renderings for your architectural and real estate projects. Through our platform, you can quickly request high-quality CGI images that accurately capture the essence of your designs. Whether it's for a residential or commercial property, our experts specialize in creating realistic 3D renderings that highlight every detail, bringing your vision to life with exceptional clarity and precision.

Through our website, requesting photorealistic CGI becomes a seamless experience. With our help, you can get highly detailed 3D visualizations that look just like photographs, providing a realistic representation of your project before it's even built. Our team ensures that every element, from textures to lighting, is meticulously rendered, giving you an impressive, lifelike result that will leave a lasting impact on your clients and stakeholders.

Leave a Reply

You must be logged in to post a comment.